| Items |

TFH-M3-6ZI

Non-Flush Studs - Types TFH, TFHS - Metric

|

TFH-M3-8ZI

Non-Flush Studs - Types TFH, TFHS - Metric

|

TFH-M4-8ZI

Non-Flush Studs - Types TFH, TFHS - Metric

|

TFH-M5-8ZI

Non-Flush Studs - Types TFH, TFHS - Metric

|

TFH-M3-10ZI

Non-Flush Studs - Types TFH, TFHS - Metric

|

|

Thread Size x Pitch

|

N/A

M3 x 0.5

|

N/A

M3 x 0.5

|

N/A

M4 x 0.7

|

N/A

M5 x 0.8

|

N/A

M3 x 0.5

|

|

Thread Code

|

N/A

M3

|

N/A

M3

|

N/A

M4

|

N/A

M5

|

N/A

M3

|

|

Length Code

|

N/A

6

|

N/A

8

|

N/A

8

|

N/A

8

|

N/A

10

|

|

Material Code

|

N/A

|

|

Min. Sheet Thickness

|

N/A

0.51 mm

|

|

Hole Size in Sheet + 0.08

|

N/A

3 mm

|

N/A

3 mm

|

N/A

4 mm

|

N/A

5 mm

|

N/A

3 mm

|

|

Max. Hole in Attached Parts

|

N/A

3.3 mm

|

N/A

3.3 mm

|

N/A

4.7 mm

|

N/A

5.3 mm

|

N/A

3.3 mm

|

|

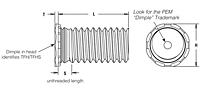

L - Length ± 0.41

|

N/A

6 mm

|

N/A

8 mm

|

N/A

8 mm

|

N/A

8 mm

|

N/A

10 mm

|

|

H ± 0.4

|

N/A

4.50 mm

|

N/A

4.50 mm

|

N/A

5.80 mm

|

N/A

6.4 mm

|

N/A

4.50 mm

|

|

S Max.2

|

N/A

1.80 mm

|

N/A

1.80 mm

|

N/A

1.80 mm

|

N/A

2.30 mm

|

N/A

1.80 mm

|

|

T Max.

|

N/A

0.64 mm

|

|

Min. Dist. Hole C/L to Edge3

|

N/A

5.6 mm

|

N/A

5.6 mm

|

N/A

7.2 mm

|

N/A

7.2 mm

|

N/A

5.6 mm

|

|

For Use in Sheet Hardness

|

N/A

HRB 80 / HB 150 or less

|

|

Thread Specification

|

N/A

External, ASME B1.13M, 6g

|

|

Fastener Material

|

N/A

Heat-Treated Carbon Steel

|

|

Standard Finish

|

N/A

Zinc plated per ASTM B633, SC1 (5µm), Type III, colorless

|

|

Optional Finish4

|

N/A

|

|

CAD Supplier

|

N/A

PennEngineering® (PEM®)

|